Robotics Systems In NDT

Our Case Studies

Advanced NDT Services Article

At MasterScan, we recognize the importance of advanced Non-Destructive Testing (NDT) techniques in ensuring the safety and integrity of infrastructure and equipment in the oil and gas industry. While traditional NDT methods have long served as the backbone of flaw...

Conventional NDT Services Article

At MasterScan, we understand the critical role that Non-Destructive Testing (NDT) plays in ensuring the safety, reliability, and efficiency of operations in the oil and gas industry. By employing various NDT techniques, we help companies detect flaws, corrosion, and...

Robotics In NDT

Why Robotics in NDT

Precision and Efficiency:

- Robotic systems offer precise movements and consistent performance.

- They can carry out inspections with high accuracy, reducing human error.

Safety:

- Robots can access hazardous environments, eliminating risks to human inspectors.

- Think of them as our fearless explorers in radioactive zones or confined spaces.

Difficult-to-Reach Areas:

- Robots can navigate tight spaces, crawl through pipes, and explore nooks and crannies that would challenge even the most agile human inspector.

Multipurpose Use:

- These mechanical marvels aren’t one-trick ponies.

- They can handle various tasks, from surface scanning to vision-driven applications.

Equipment We Use

Types of Robotic Systems in NDT

Robotic Arms:

- These versatile arms can perform manipulation, specific picking, surface scanning, and more.

- They’re like the Swiss Army knives of NDT.

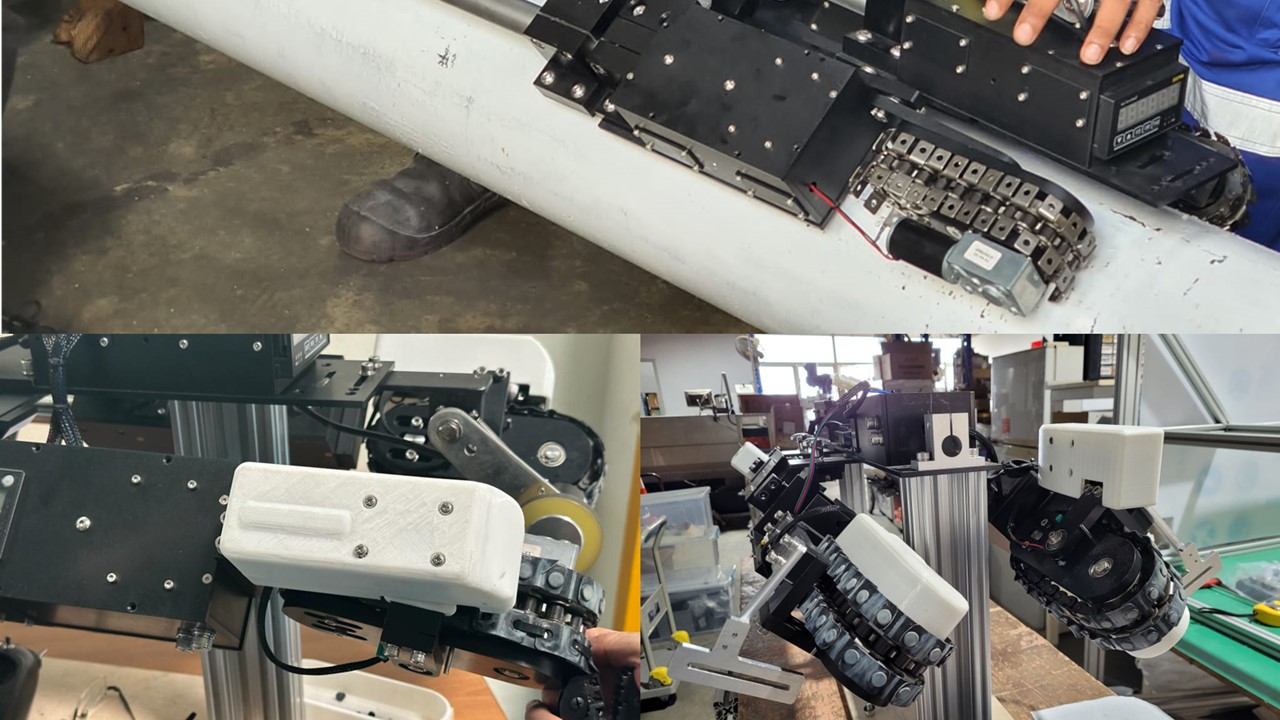

Crawlers:

- Imagine tiny, tireless creatures crawling along pipes, tanks, and other structures.

- These robotic crawlers inspect hard-to-reach areas and internal obstructions.

Vision-Driven Robots:

- Equipped with advanced sensors and cameras, these robots “see” defects and anomalies.

- They’re like the eagle-eyed detectives of NDT.

Real World Applications

Robotic systems are deployed in various NDT scenarios:

Weld Inspections:

- Robots scan welds for cracks, porosity, and other imperfections.

Tank and Pipeline Inspections:

- Crawlers explore the insides of storage tanks and pipelines.

Aircraft Maintenance:

- Robots check aircraft surfaces and components.

Bridge and Infrastructure Inspections:

- Crawlers climb bridges and tunnels, ensuring their structural integrity.

Advantages of Robotics in NDT

Safety

Robots take the risks, keeping humans out of harm’s way.

Data Analysis

Real-time data helps maintain structural integrity.

Efficiency

They work tirelessly, reducing inspection time.

Automation

Customers increasingly seek fully automated procedures.

Why Masterscan?

Choose Masterscan for cutting-edge NDT solutions. Our experienced technicians ensure thorough inspections and accurate defect detection.

Revolutionise Your Project with Masterscan!

Step into the future of non-destructive testing with Masterscan.

We’re dedicated to pushing the boundaries of innovation and precision in every inspection we conduct.