Radiographic Testing

Our Case Studies

Advanced NDT Services Article

Conventional NDT Services Article

Radiographic Testing Services

What Is Radiographic Testing

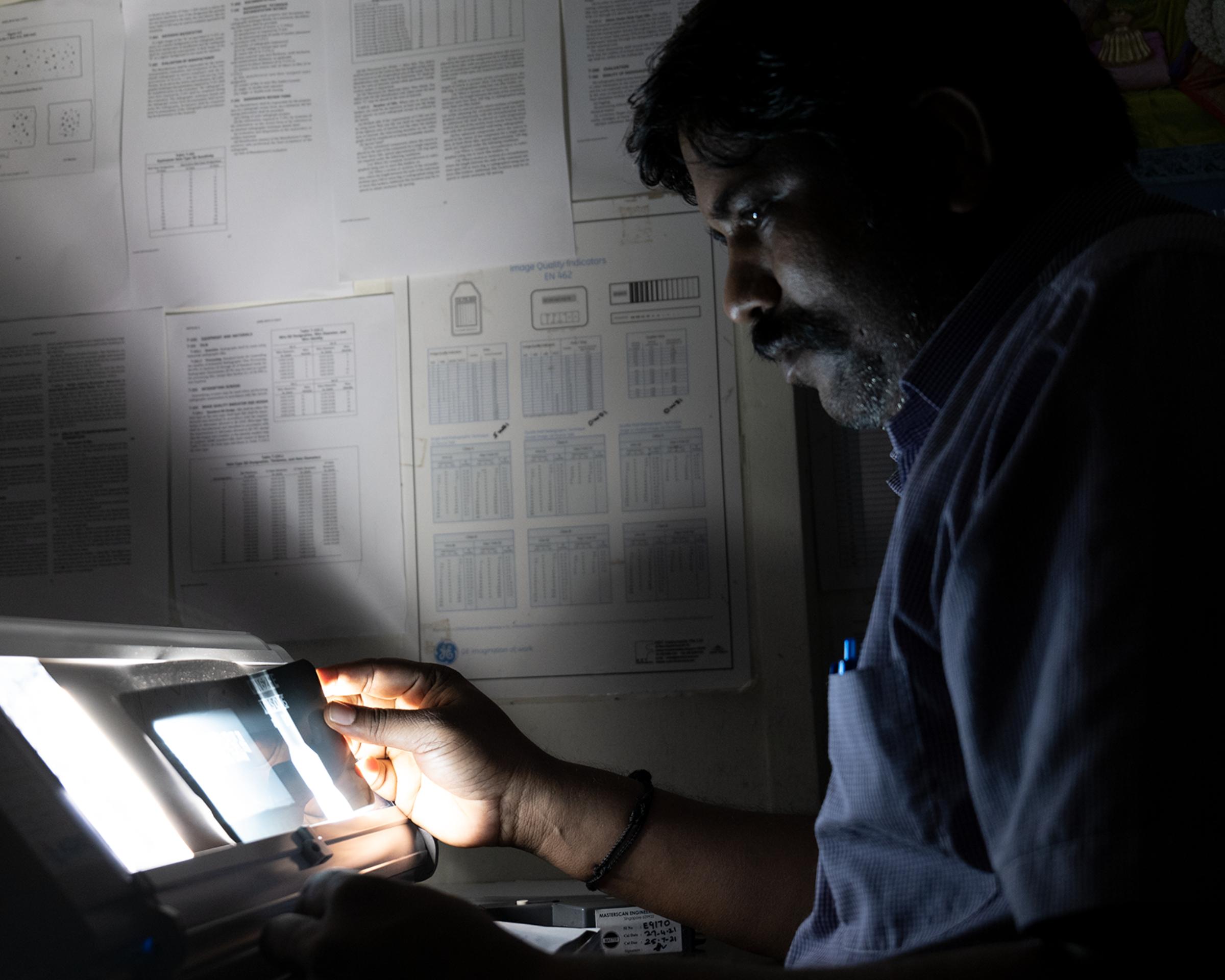

Radiographic Testing (RT), also known as Radiographic Examination, is a sophisticated non-destructive testing (NDT) method that uses x-rays or gamma rays to inspect the internal structure of components. This technique is essential for identifying hidden flaws with precision.

How It Works:

- A test part is placed between a radiation source and a sensitive detector.

- The interaction of radiation with material density and thickness creates a detailed radiograph.

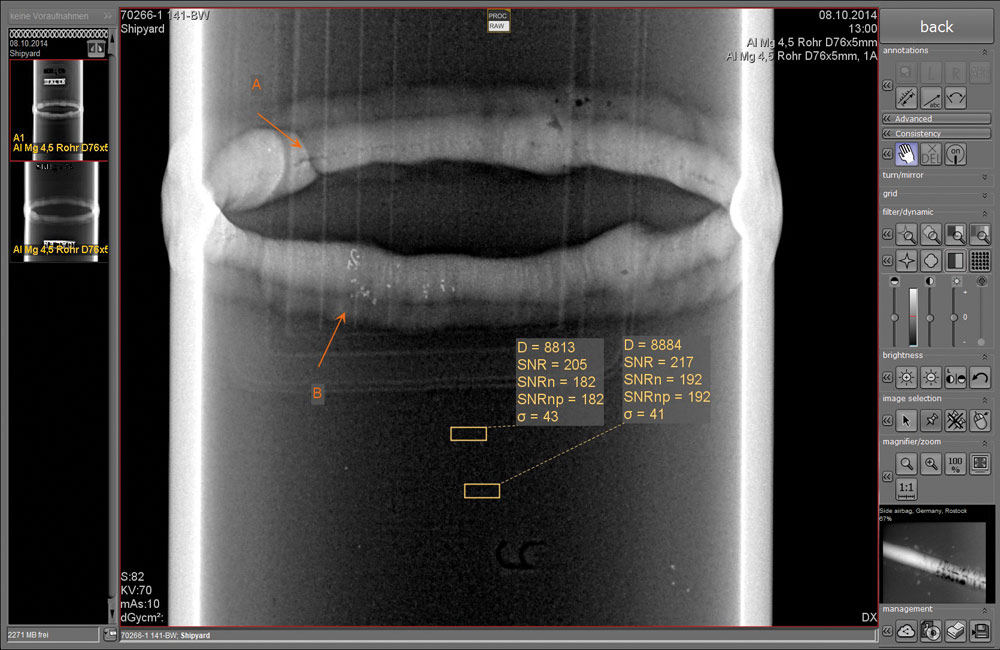

- Variations in density on the radiograph highlight defects, ensuring accurate detection.

Equipment We Use

Equipments and Procedure

Our RT process involves:

- A high-quality radiation source for clear imaging.

- A test specimen positioned for optimal exposure.

- Advanced recording mediums to capture detailed radiographs.

Defect Detection

- Analyzing the radiograph reveals defects, ensuring the integrity of your components.

RT Inspection Application

RT is invaluable for;

Weld Inspection:

Detecting interior weld defects like cracks and voids.

Industry Practices:

Serving sectors such as oil & gas, aerospace, and manufacturing with reliable testing.

Advantages of Choosing RT

Safety Considerations:

Safety is our top priority

We adhere to strict protocols when handling high-energy radiation to protect our team and your assets.

Why Masterscan?

Choose Masterscan for dependable Radiographic Testing services. Our commitment to safety and quality ensures the integrity of your components across various industries.

Kickstart Your Project with Masterscan!

Ready to elevate your project with cutting-edge non-destructive testing?

Look no further! At Masterscan, we pride ourselves on delivering excellence and innovation in every inspection.