Conventional NDT

Conventional Non-Destructive Testing (NDT)

Conventional Non-Destructive Testing (NDT), also known as Non-Destructive Examination (NDE), Non-Destructive Inspection (NDI), or Non-Destructive Evaluation (NDE), is a collection of analysis techniques used in the oil and gas industry to evaluate the properties of a material, component, or system without causing damage.

Services We Provide

Conventional NDT

Ultrasonic Testing (UT)

Precision and Reliability in Flaw Detection and Material Assessment

Conventional NDT

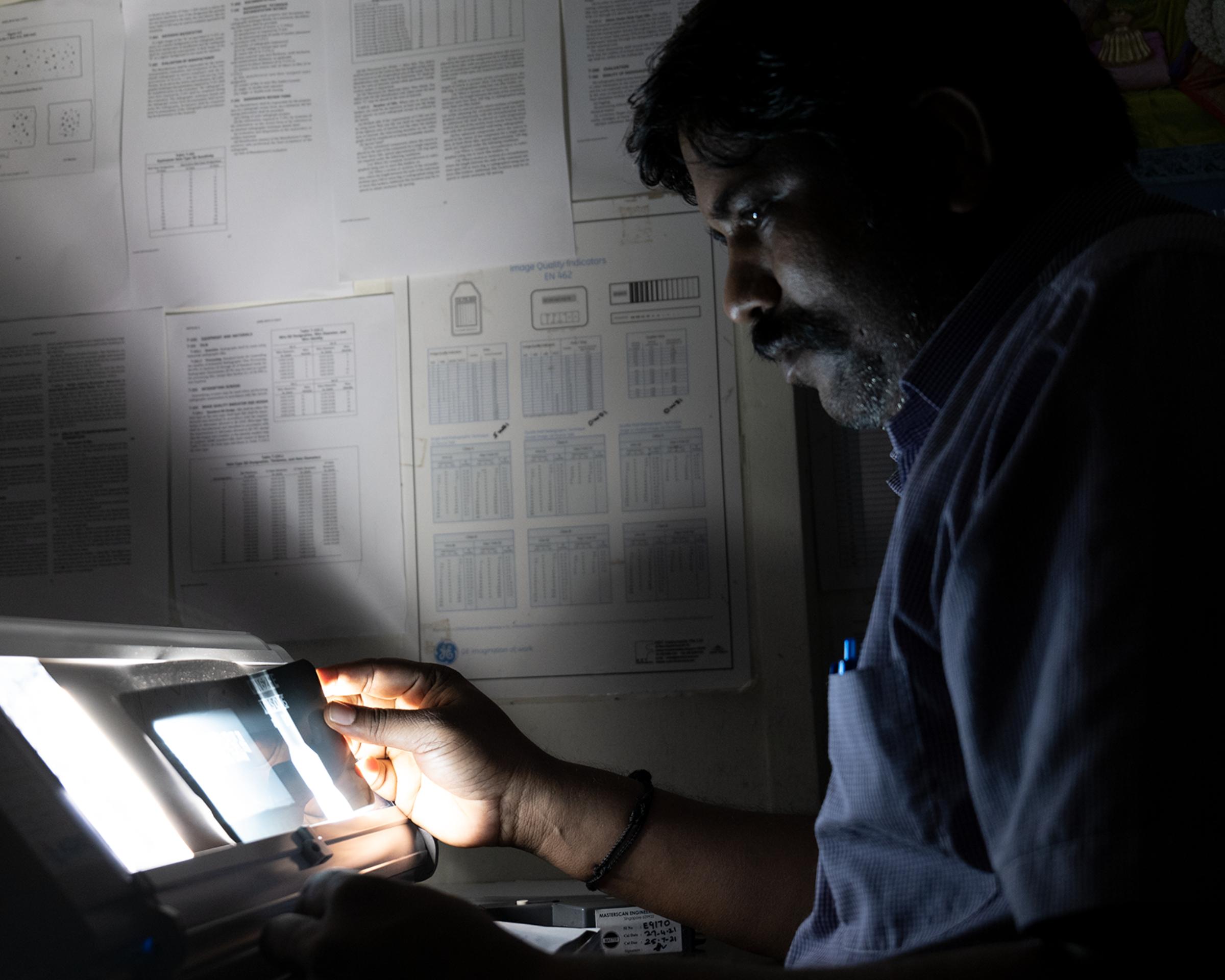

Radiography Testing (RT)

In-depth Inspection for Flawless Integrity

Conventional NDT

Magnetic Particle Testing (MT)

Discovering Flaws with Precision and Speed

Conventional NDT

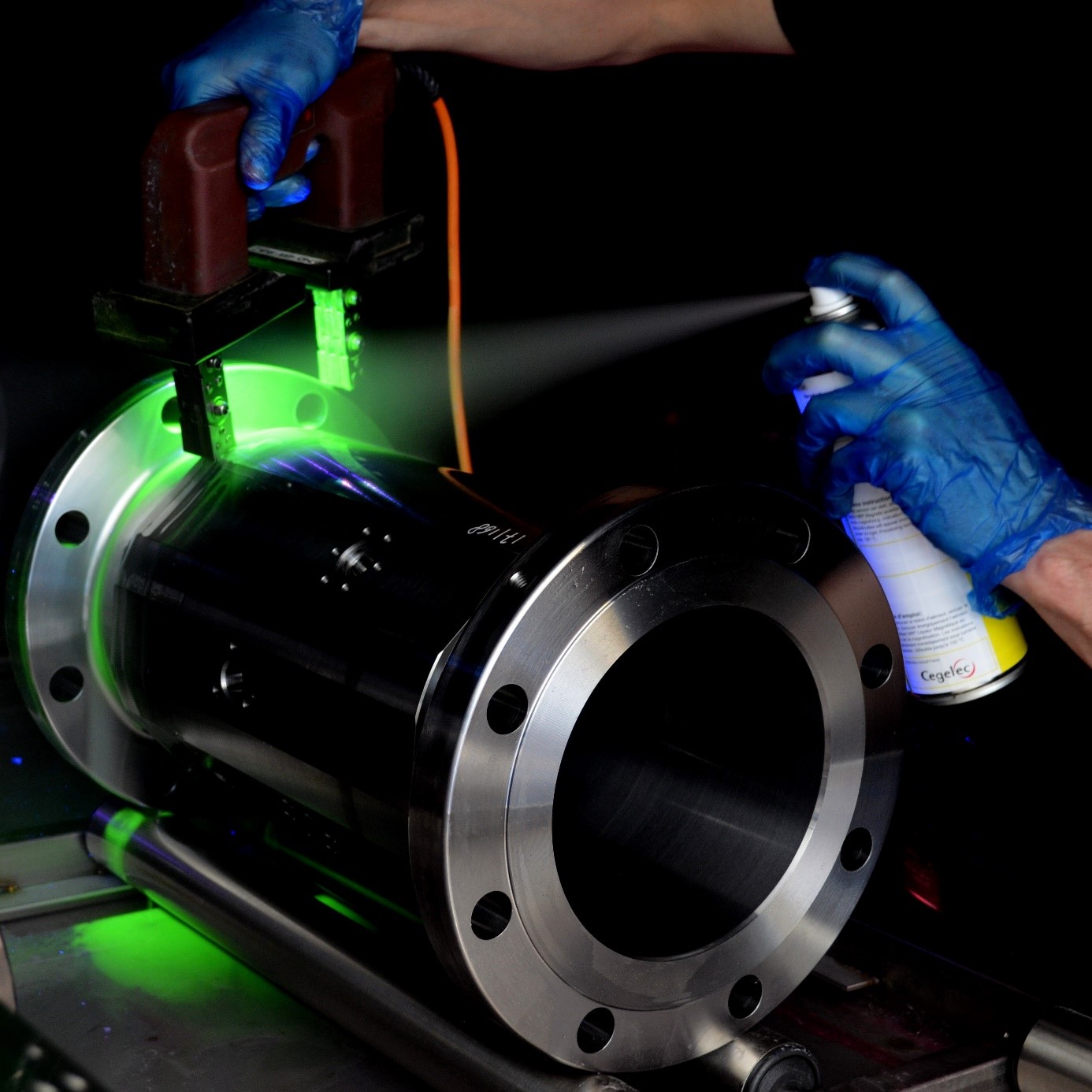

Fluorescent Magnetic Particle Inspection (FMPI)

Discovering Flaws with Precision and Speed

Conventional NDT

Liquid / Dye Penetrant Testing (PT)

Unveiling Surface Flaws with Clarity and Precision

Conventional NDT

Visual Testing and Borescopes (VT)

Clarity in Inspection, Excellence in Detection

Conventional NDT

Positive Material Identification (PMI)

Ensuring Material Integrity with Advanced Analytical Techniques

Conventional NDT

Holiday Testing

Detecting the Undetectable in Coatings and Paints

Conventional NDT

Hardness Testing

Assessing Material Strength with Precision and Expertise

Conventional NDT

Ultrasonic Thickness Gauging (UTG)

Precision in Measurement, Confidence in Integrity

Conventional NDT

Ferrite Testing Services

Determine the ferrite content in stainless steel and

ensuring optimal performance

Conventional NDT

Heat Treatment Services

Ensuring Excellence in Welding Through Advanced Heat Treatment