Computerised Radiography Testing

Our Case Studies

Advanced NDT Services Article

Conventional NDT Services Article

Computerised Radiography Testing Services

What Is CRT

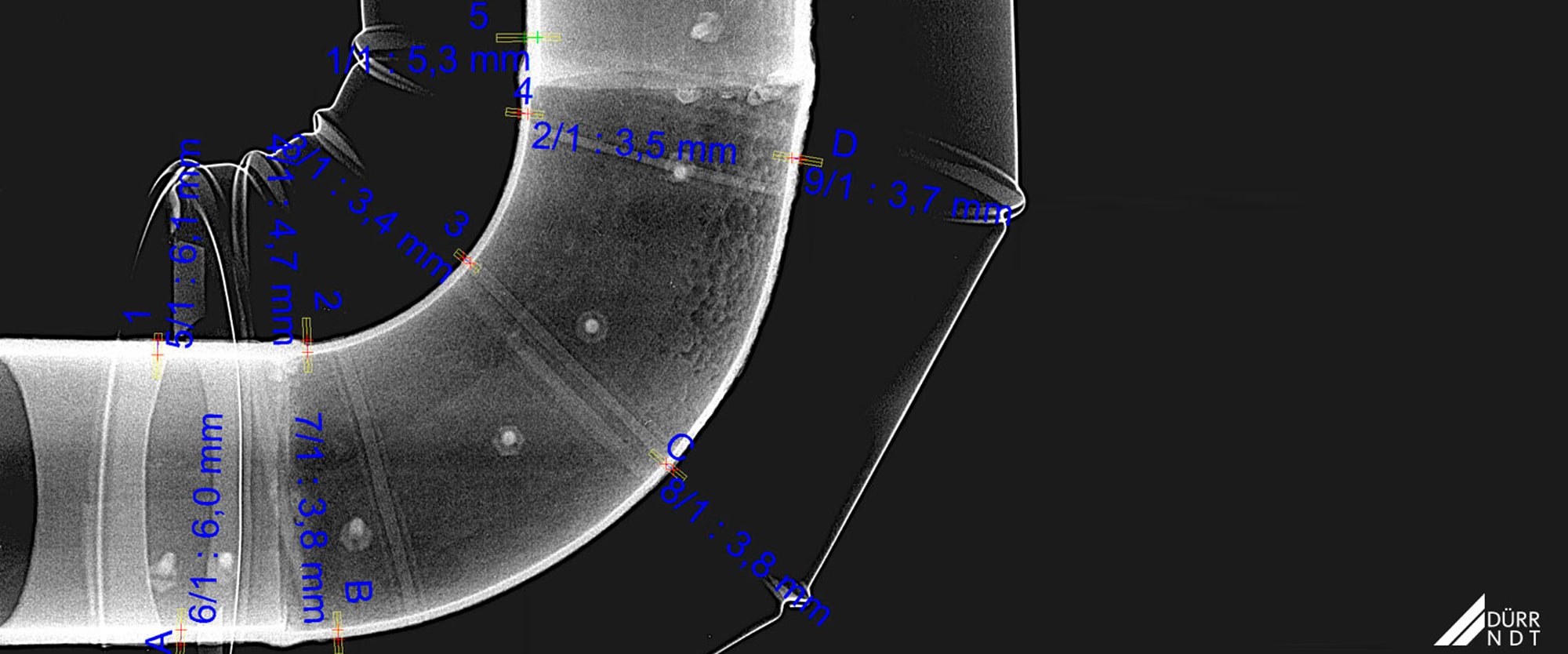

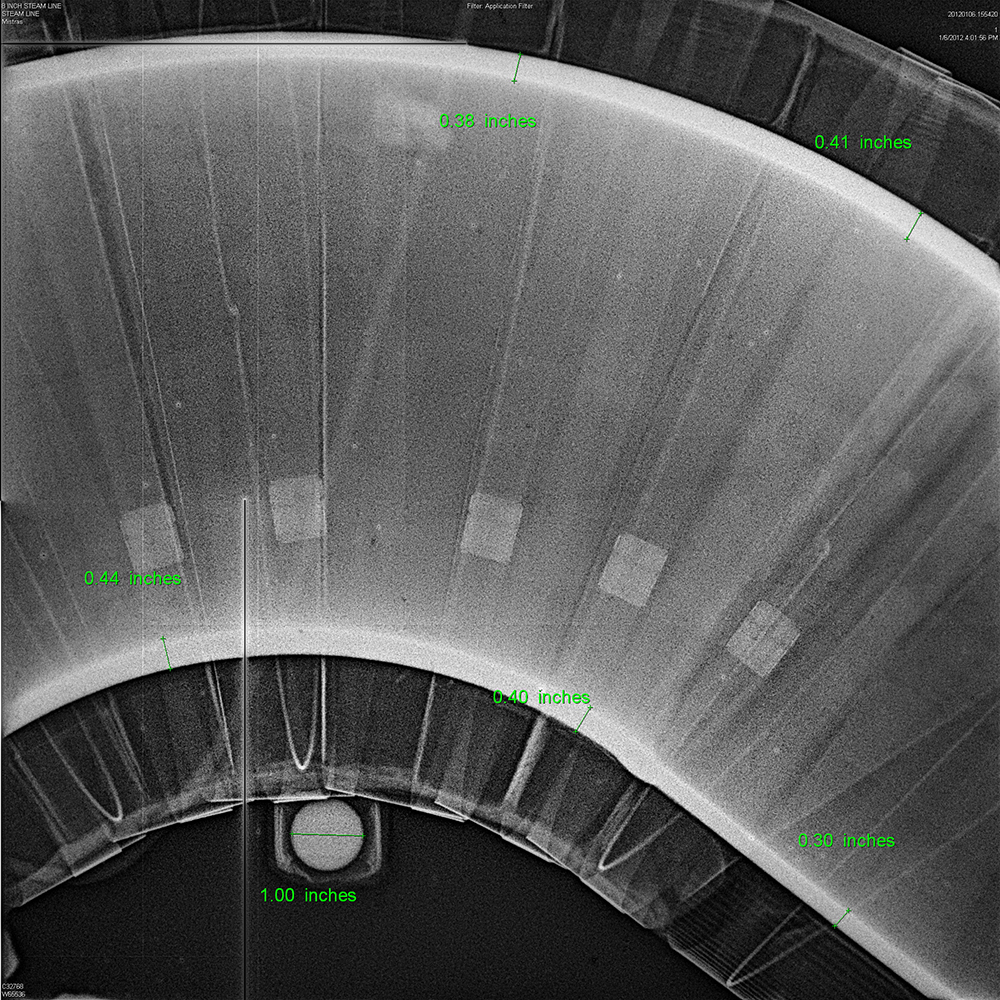

CRT employs a phosphor imaging plate for non-destructive testing of pipes and tubes.

Suitable for both ferrous and non-ferrous materials.

Equipment We Use

How CRT Works:

Radiation Exposure:

- During inspection, an imaging plate is exposed to X-ray or gamma radiation.

Image Storage:

- The phosphor layer within the plate temporarily stores the X-ray image.

Digitisation:

- A computer system scans the exposed plate, converting the image into a digital format.

Plate Reuse:

- Post-scan, the plate is cleared and readied for immediate reuse.

Advantages of Choosing CRT

Digital Workflow

Eliminates the need for physical X-ray films, enhancing the inspection workflow.

Sustainable Reuse

Imaging plates can be reused, minimizing waste and expenses.

Enhanced Safety

Reduces exposure to harmful chemicals associated with film processing.

Instant Results

Digitized images are available for immediate analysis.

Efficient Storage

Streamlines data storage and retrieval processes.

Why Masterscan?

Masterscan’s CRT services offer flaw detection with unparalleled clarity and efficiency. Our state-of-the-art technology and expert technicians ensure accurate inspections across various industries.

For more information on our CRT capabilities or to schedule an inspection, contact Masterscan today. We’re committed to excellence in non-destructive testing and ensuring the integrity of your assets.

Ignite Your Project with Masterscan!

Are you ready to transform your project with the latest non-destructive testing technology? Masterscan is your go-to partner for precision, innovation, and excellence in every inspection.