Phased Array Ultrasonic Testing

Our Case Studies

Advanced NDT Services Article

Conventional NDT Services Article

Phased Array Ultrasonic Testing Services

What Is PAUT

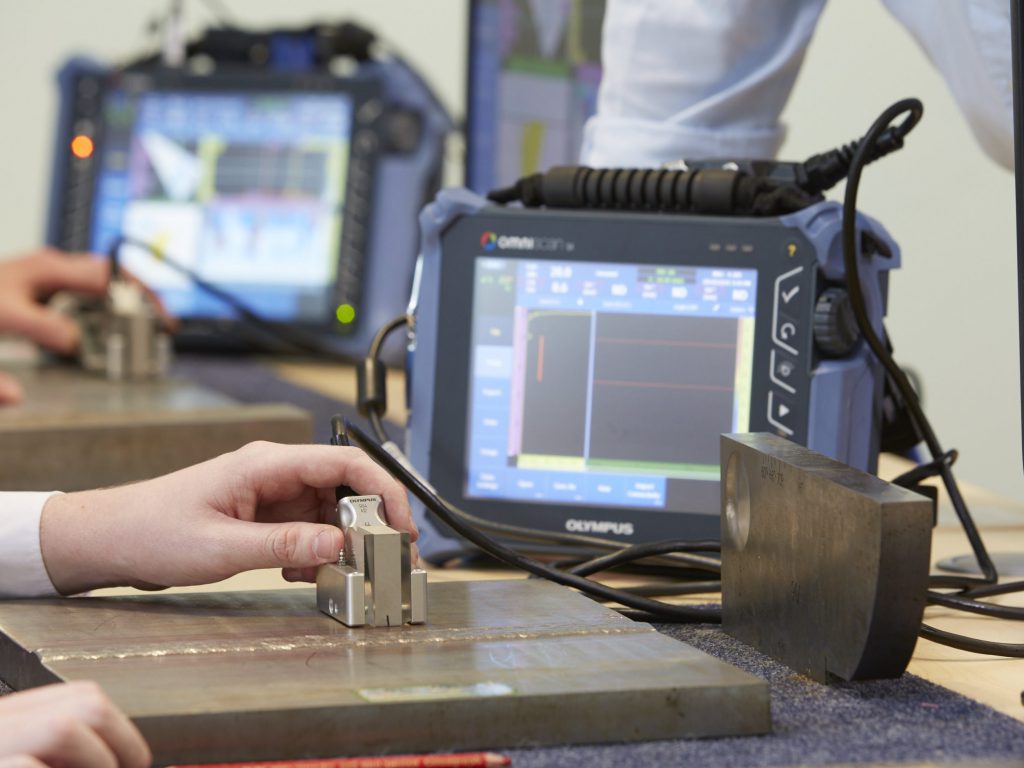

Phased Array Ultrasonic Testing (PAUT) is an advanced method of ultrasonic testing that offers several advantages over traditional single-probe ultrasound techniques.

PAUT utilises a set of ultrasonic probes composed of numerous small elements.

By applying time delays to piezoelectric crystals, PAUT focuses ultrasonic beams at precise depths and angles.

Equipment We Use

How PAUT Works:

Instead of using a single large probe, PAUT employs an array of small individual crystals (transducers). These crystals can send and receive sound waves independently at different times.

By controlling the timing of each crystal, a computer creates a focused and moving ultrasound beam. This beam can scan an object without physically moving the entire probe.

The ability to electronically steer and focus the sound beam allows for precise inspection at various depths and angles within the test object.

Extensive Inventory to Accommodate Varied Applications

- Machines, Probes, Manuals and Robotic Scanners

Technical Expertise at Masterscan Engineering

- ASNT Level II / IIIs & PCN Level 2s / 3s

- Combined Experience of over 50 Years

- Quality from Within

- Our Inspectors regularly go through internal tests and mockups before they are mobilised for projects.

- Varied Experience & Combined Expertise

PAUT Application

Industries Using PAUT:

PAUT finds applications in various industries, including:

- Construction

- Oil and gas

- Marine

- Power plants

- Aerospace

- Automotive manufacturing

Utilised In:

Weld Inspection:

- PAUT is commonly used for inspecting butt welds in pipes, pressure vessels, and large structures.

Corrosion Mapping:

- It estimates thickness at finite points in pressure vessels, pipes, tanks, and other structures.

Complex Geometries:

- PAUT can scan painted cylindrical or trapezoidal fuel transport tankers and other intricate shapes.

High-Pressure and High-Temperature Piping:

- Inspections at power station sites, focusing on circumferential and seam welds.

Branch Welds and Variable Profiles:

- Accurate sizing of internal defects in complex geometry branch welds.

Turbine and Generator Components:

- Special focus on areas of high stress concentration, such as turbine blade roots.

Shafts, Axles, and Spindles:

- In-site inspection for transverse cracks and precise detection.

Total Focusing Method (TFM) – Defect sizing for remaining life calculations

Robotic Weld Inspection

Advantages of Choosing PAUT

Ease of Use and Mobility

PAUT systems are easier to handle, and maneuverer compared to traditional probes. Technicians can inspect complex geometries without physically repositioning the probe.

Safety

Unlike some other testing methods (such as X-rays), PAUT doesn’t involve radiation exposure.

Accurate Sizing and Mapping

It provides precise defect sizing and mapping capabilities.

Faster Inspections

Electronic scanning enables rapid coverage of large areas, reducing inspection time.

Improved Detection

PAUT can detect internal defects (such as cracks, voids, or inclusions) more effectively than conventional probes.

Customization

PAUT allows for individually tailored development of qualification blocks and specific configurations for data collection and post-analysis reporting.

Multiple Views like S, C, and B Scans.

Why Masterscan?

In advanced NDT, Phased Array Ultrasonic Testing continues to enhance inspection efficiency and safety.

Contact Masterscan today to learn more about our PAUT capabilities or to schedule an inspection. We’re dedicated to providing you with the highest quality of service and detailed insights into your critical machinery.

Ignite Your Project with Masterscan!

Are you ready to transform your project with the latest non-destructive testing technology? Masterscan is your go-to partner for precision, innovation, and excellence in every inspection.