Pulsed Eddy Current Testing

Our Case Studies

Advanced NDT Services Article

Conventional NDT Services Article

Pulsed Eddy Current Testing Services

What Is PEC

PEC is an electromagnetic inspection technique used to detect wall loss on ferromagnetic structures such as carbon steel and cast iron.

It provides a relative volumetric measurement converted into an averaged thickness measurement based on the calibration area.

Equipment We Use

How PEC Works:

Magnetic Field Creation:

- A magnetic field is created by an electrical current in the coils of the probe.

Penetration and Stabilization:

- This field penetrates through layers like cladding and non-conductive insulation (e.g., concrete, silicate).

- It stabilizes within the component thickness.

Eddy Currents Induction:

- The emission is then cut off, inducing eddy currents captured by the probe.

Signal Processing:

- The decay rate of these currents is measured.

- An advanced signal processing algorithm translates the electromagnetic signal into an average thickness reading over the probe’s footprint.

PEC Application

Essential for:

Corrosion Under Insulation (CUI) and Fireproofing (CUF):

- PEC excels in detecting hidden corrosion beneath insulation coatings, paints, and concrete fireproofing.

- It assesses the condition of structures without requiring direct contact or surface preparation.

Scab and Blister Assessment:

- PEC can identify scabs and blisters, even achieving the smallest footprint ever recorded in pulsed eddy current inspections.

Advantages of Choosing PEC

Versatility

It can measure remaining thickness through various non-ferromagnetic forms, including:

- Insulation with weather jackets (aluminium, stainless steel, galvanized steel)

- Concrete/silicate

- Composite wrap/polymer coating

Non-Intrusive

PEC does not require direct contact, cleaning, or special surface preparation.

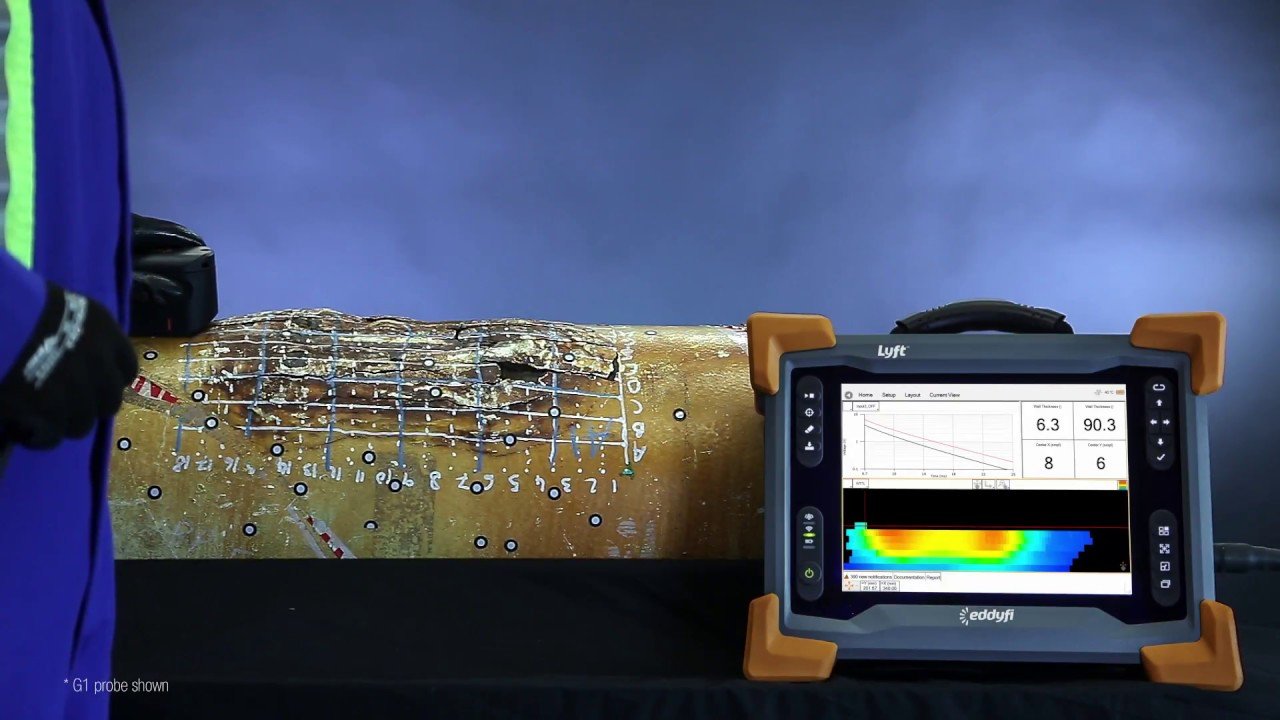

State-of-the-Art Solution

The Eddyfi Lyft® instrument offers an easy-to-deploy, high-performance PEC system.

It requires no surface preparation, including coating or insulation removal.

Inspections can be performed while assets are in service, even at temperatures up to 120°C (250°F).

Why Masterscan?

In advanced NDT, Pulsed Eddy Current continues to revolutionize how we assess and maintain critical structures. Its ability to detect hidden flaws without intrusive methods makes it an indispensable tool for engineers and inspectors.

For more information on our PEC capabilities or to schedule an inspection, contact Masterscan today. We’re dedicated to providing you with the highest quality of service and detailed insights into your critical machinery.

Ignite Your Project with Masterscan!

Are you ready to transform your project with the latest non-destructive testing technology? Masterscan is your go-to partner for precision, innovation, and excellence in every inspection.