Real-Time Radiography

Our Case Studies

Advanced NDT Services Article

Conventional NDT Services Article

Real-Time Radiography Services

What Is RTR

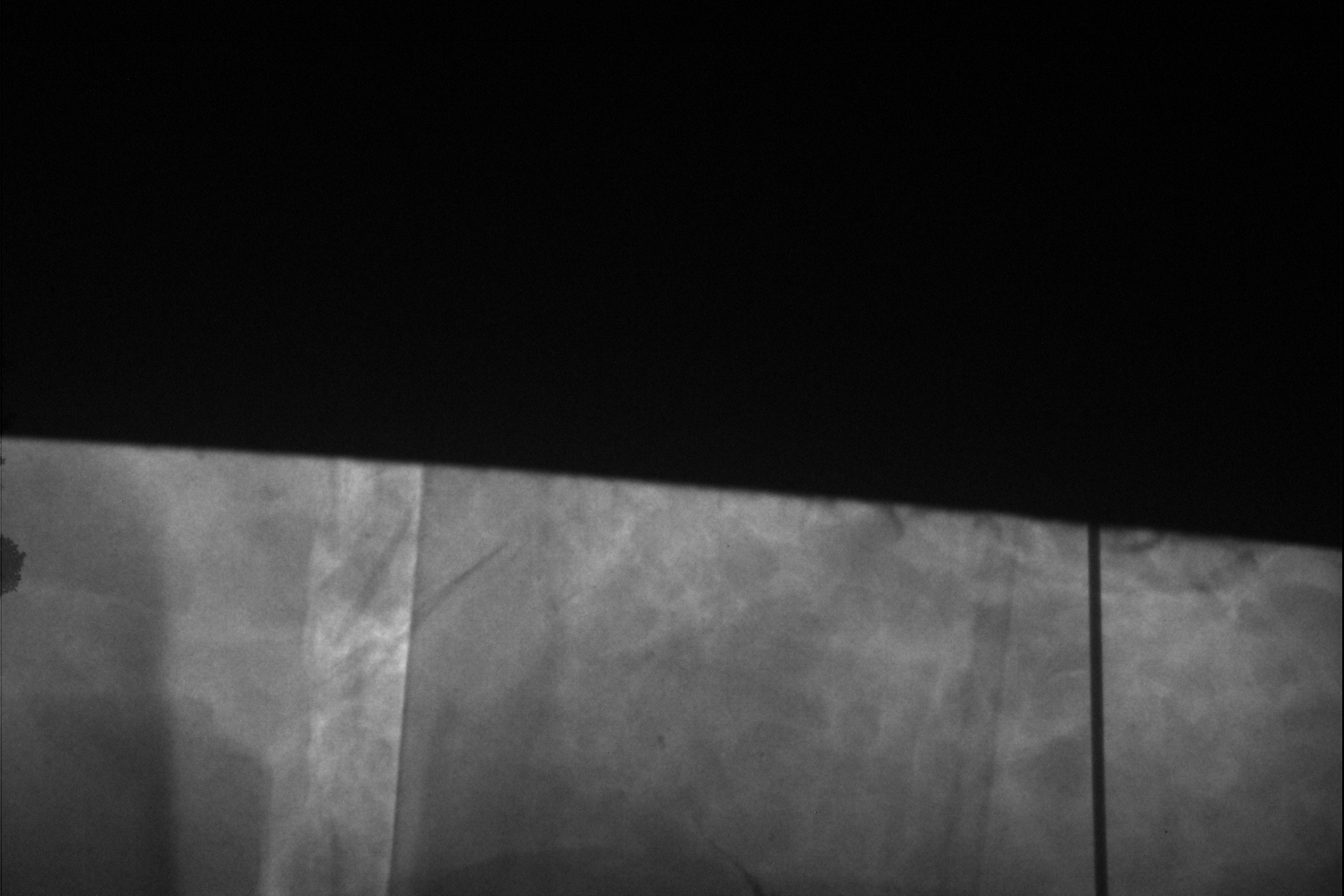

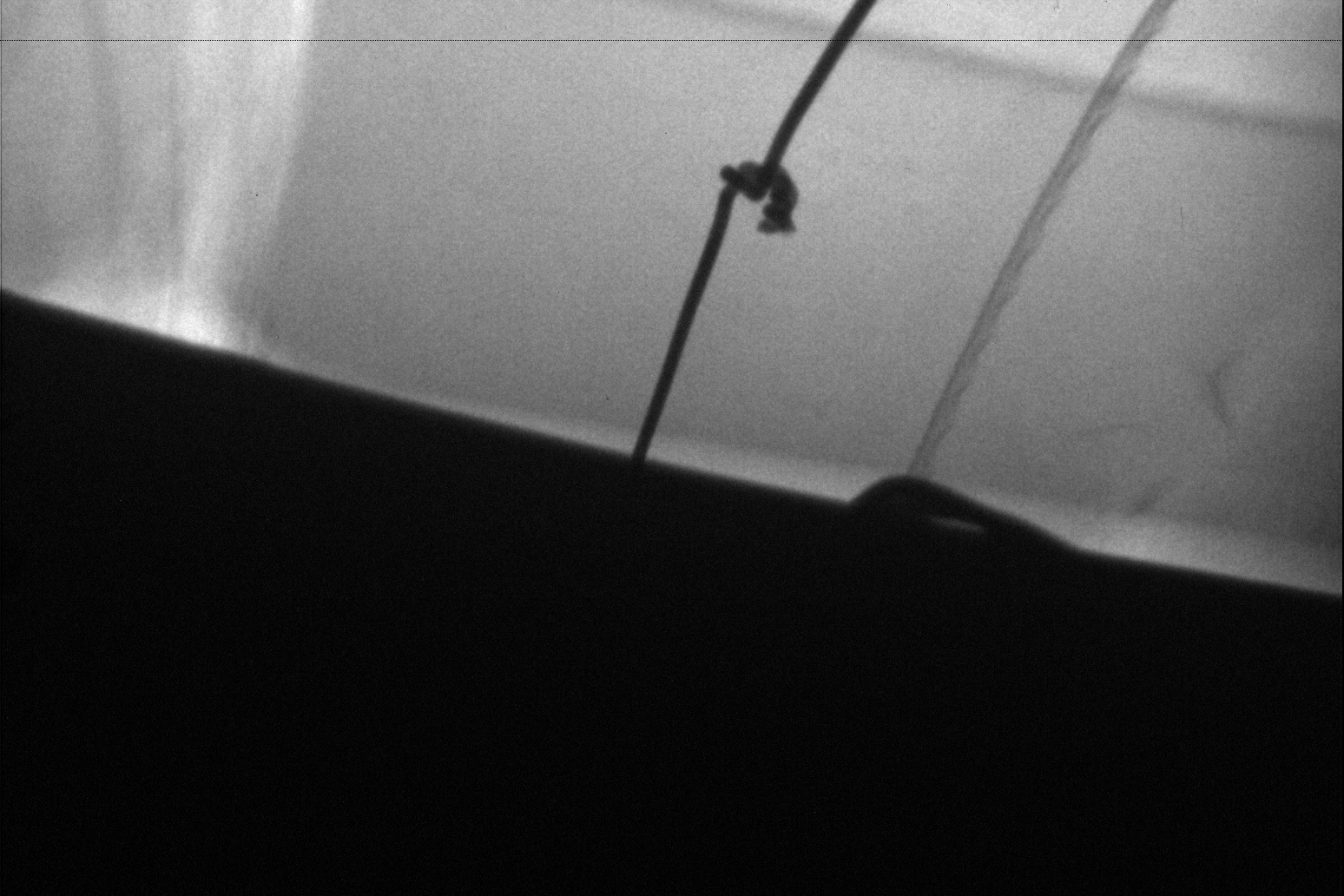

RTR, also known as real-time radioscopy, is an NDT method where an image is produced electronically rather than on film.

Unlike traditional X-ray imaging, RTR provides immediate results with minimal lag time between radiation exposure and image display.

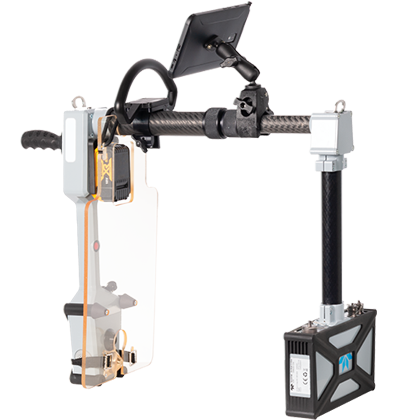

Equipment We Use

How RTR Works:

Radiation Interaction:

- Radiation passes through the object being inspected and interacts with a fluorescent screen.

Fluorescence and Image Formation:

- The screen fluoresces or emits light where the interaction occurs, forming a positive image.

- Brighter areas on the image represent thinner or less dense sections of the test object.

RTR Application

Our services include:

Infrastructure Inspections:

- RTR assesses structures for defects, such as corrosion, cracks, or voids, without the need for film development.

- Particularly useful for cross-country pipeline projects.

Safety-Critical Components:

- RTR inspects components in aerospace and automotive industries, ensuring their integrity.

- Detects flaws in welds, castings, and composite materials.

Digital Imaging Advantages:

- RTR produces digital images that can be viewed, shared, and edited using electronic devices.

- Faster than conventional X-ray imaging.

- Safer, using up to 80% less radiation.

Advantages of Choosing RTR

Immediate Results

RTR provides real-time images, allowing for quick decision-making during inspections.

Reduced Radiation Exposure

Safer for operators and the environment.

Wide Range of Applications

From critical infrastructure to industrial components.

Digital Format

Images are easily stored, shared, and analyzed digitally.

Optimized Storage

No need for physical film storage.

Why Masterscan?

In advanced NDT, Real-Time Radiography continues to enhance inspection efficiency and safety. Its real-time capabilities make it indispensable for quality control and ensuring the integrity of critical machinery and structures.

For more information on our RTR capabilities or to schedule an inspection, contact Masterscan today. We’re dedicated to providing you with the highest quality of service and detailed insights into your critical machinery.

Ignite Your Project with Masterscan!

Are you ready to transform your project with the latest non-destructive testing technology? Masterscan is your go-to partner for precision, innovation, and excellence in every inspection.