Hardness Testing

Our Case Studies

Advanced NDT Services Article

At MasterScan, we recognize the importance of advanced Non-Destructive Testing (NDT) techniques in ensuring the safety and integrity of infrastructure and equipment in the oil and gas industry. While traditional NDT methods have long served as the backbone of flaw...

Conventional NDT Services Article

At MasterScan, we understand the critical role that Non-Destructive Testing (NDT) plays in ensuring the safety, reliability, and efficiency of operations in the oil and gas industry. By employing various NDT techniques, we help companies detect flaws, corrosion, and...

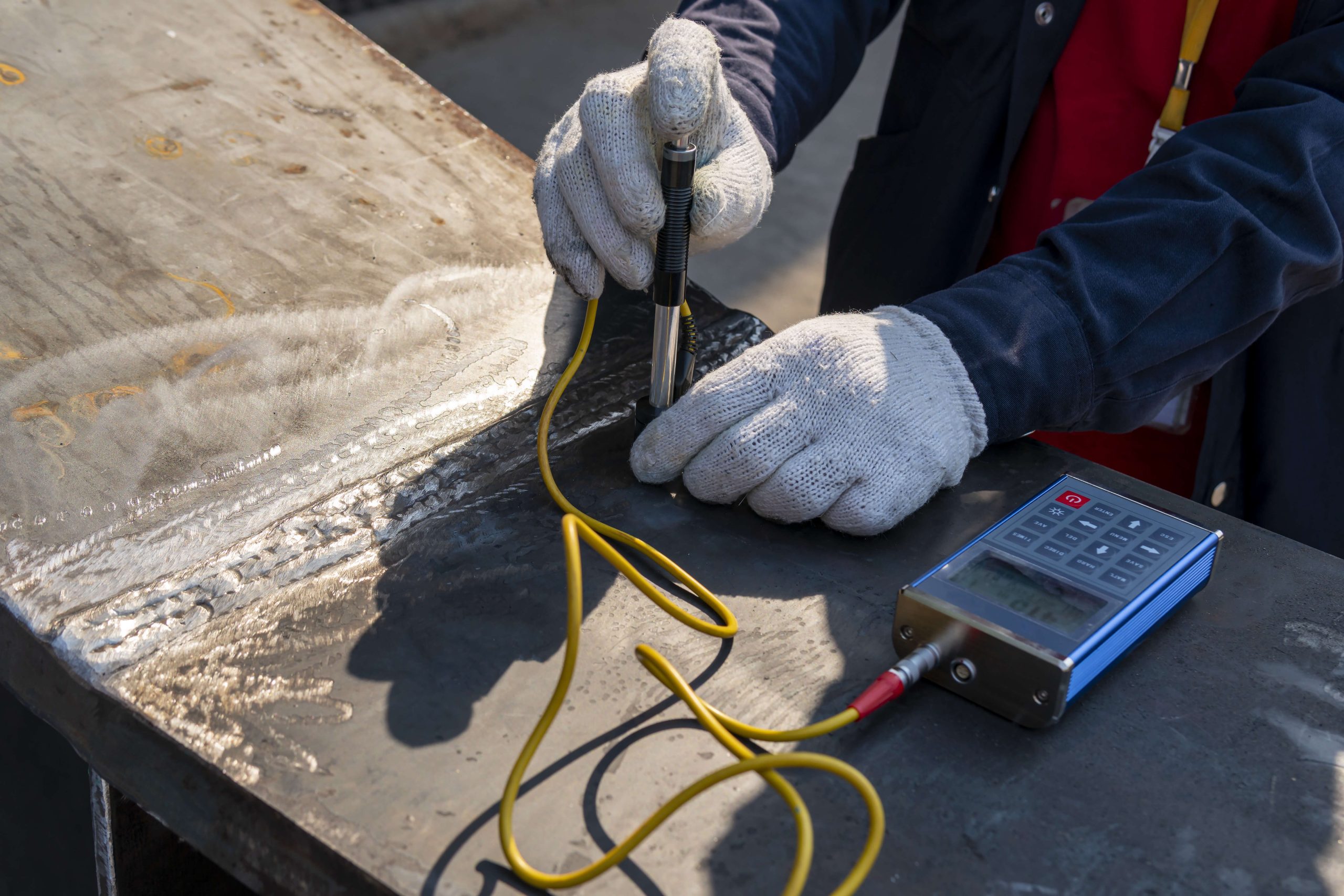

Hardness Testing Services

What Is Hardness Testing

Hardness Testing is a methodical approach to evaluating a material’s resistance to deformation. It is a critical process for determining the durability and wear resistance of various materials.

Equipment We Use

How It Works:

- A standardized indenter is pressed into the material under a specific load.

- The depth or size of the indentation is measured, providing a quantitative hardness value.

HT Application

Materials We Test

Masterscan’s Hardness Testing is applicable to a diverse range of materials, including:

- Metals and Alloys

- Ceramics

- Elastomers

- Polymers and Plastics

- Thin Films

- Rocks and Minerals

Advantages of Choosing HT

Importance of Hardness Testing

Hardness values are indispensable for:

Material Selection:

- Choosing the right material for cutting, grinding, or absorbing shocks.

Quality Control:

- Ensuring consistency and adherence to manufacturing standards.

Why Masterscan?

Choose Masterscan for comprehensive Hardness Testing services. Our advanced techniques and experienced professionals guarantee the integrity and performance of your materials.

Kickstart Your Project with Masterscan!

Ready to elevate your project with cutting-edge non-destructive testing?

Look no further! At Masterscan, we pride ourselves on delivering excellence and innovation in every inspection.