Ultrasonic Thickness Gauging via Drones

Our Case Studies

Advanced NDT Services Article

Conventional NDT Services Article

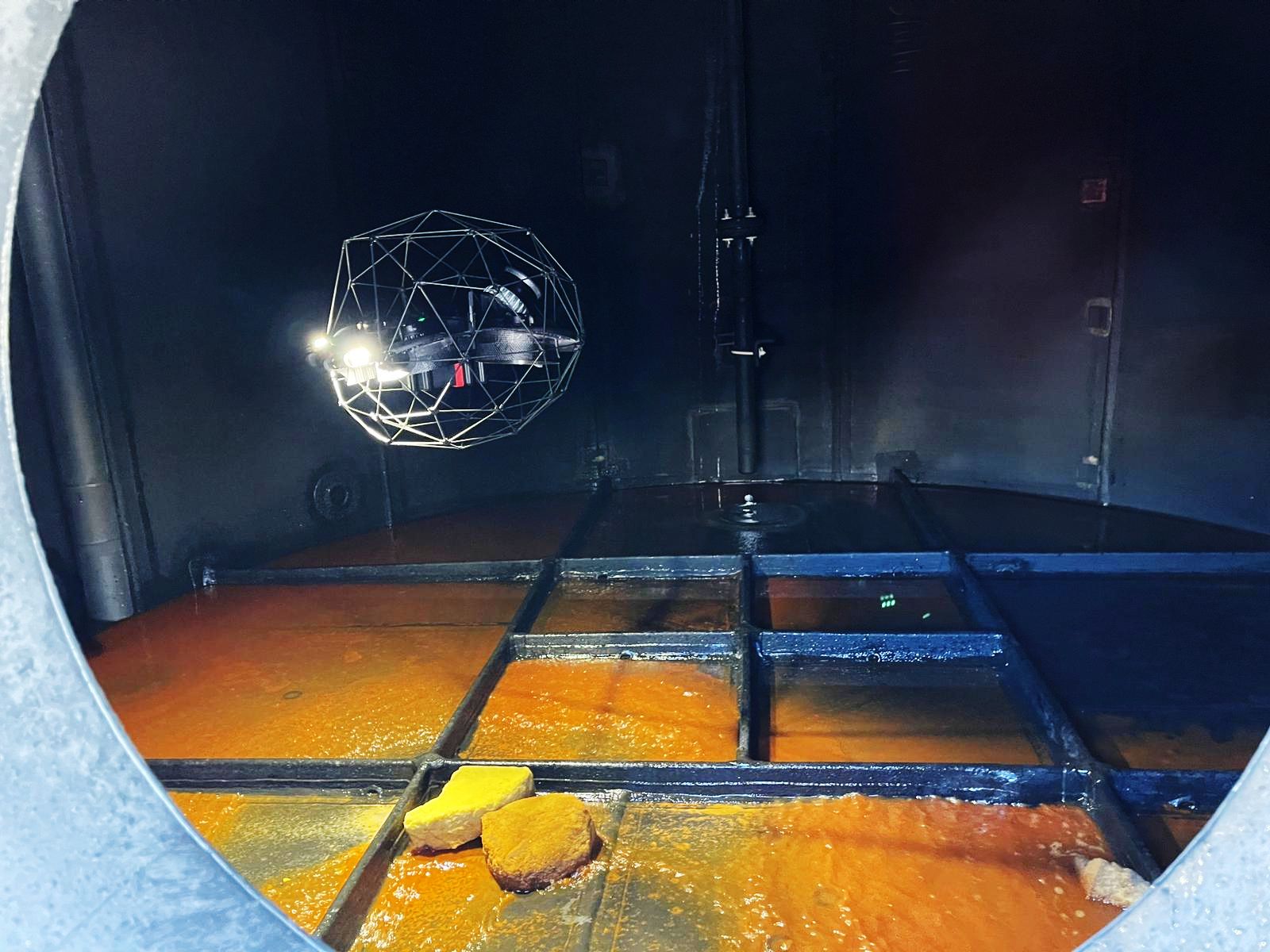

Ultrasonic Thickness Gauging via Drones – Elios 3

Safe Remote Thickness Measurements

Safety and Efficiency:

- Masterscan Services offers a safe and efficient approach to remote thickness measurements, transforming the Elios 3 drone into a potent tool for capturing A-scans in challenging environments.

Certified Inspectors:

- Our certified inspectors leverage this service to perform accurate spot thickness measurements in hard-to-reach areas, ensuring comprehensive coverage without compromising safety.

Equipment We Use

Smart Features

Location-Tagged UT Measurements:

- With precision localisation on a digital twin, our service ensures that each measurement is accurately mapped during data capture.

Smart Couplant Dispenser:

- This feature guarantees optimal ultrasound coupling by dispensing the correct amount of couplant for flawless transmission into the test material.

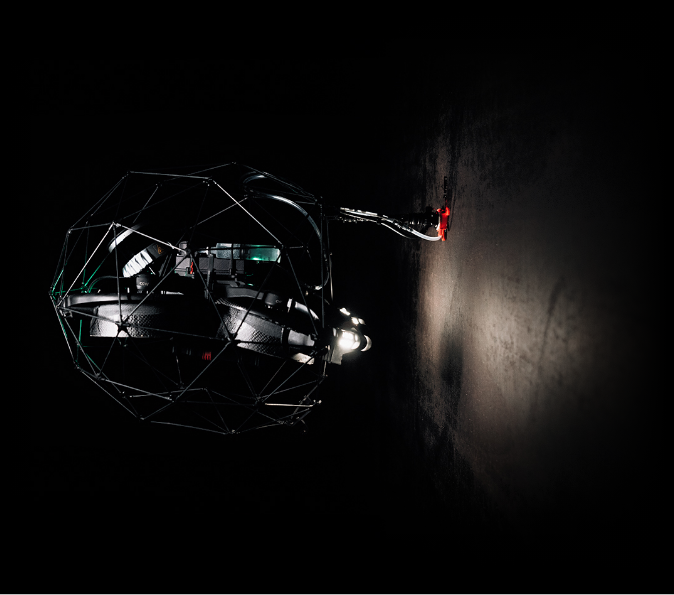

Smart Probe Arm:

- Designed to adapt to various inspection points, the probe arm can be mounted in multiple positions, ensuring uninterrupted flight and measurement accuracy.

Laser-Focused Targeting:

- The UT probe’s laser pointer aids in precise targeting during flight, enhancing the accuracy of measurements.

Applications of Elios 3

Modular Probe Head

Interchangeable Probes:

- The service includes a set of twin crystal piezo-composite probes (2MHz, 5MHz, or 7.5 MHz), suitable for a range of inspection needs.

Versatile Measurement Capabilities:

- These probes excel in measuring heavily corroded metals and can penetrate surface coatings up to 1 mm (0.040 inch), providing flexibility in various inspection scenarios.

Cleaning Module

Surface Preparation:

- The probe head can be swapped with a cleaning module to clear deposits and prepare surfaces for measurement, with location tagging for precise return to cleaned spots.

Advantages of ELIOS 3

Software Integration

Cockpit App:

Elios 3’s Cockpit app offers real-time visualisation of live A-scans and allows manual adjustments for gain and gates, enhancing control over the inspection process.

Safety Compliance

ISO 16809 Standards:

Our service adheres to ISO 16809 standards, ensuring the highest levels of accuracy, quality, and reliability in thickness gauging.

Why Masterscan?

Masterscan Services is at the forefront of ultrasonic testing in confined spaces, providing real-time analysis, advanced mapping capabilities, and seamless surface preparation to revolutionise the industry.

Elevate Your Project with Masterscan!

Unlock the potential of your project with Masterscan’s cutting-edge non-destructive testing solutions.

We’re committed to driving innovation and precision in every inspection we perform.